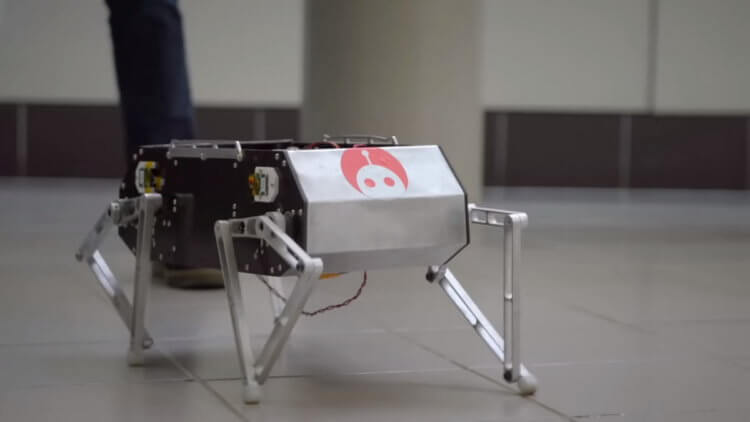

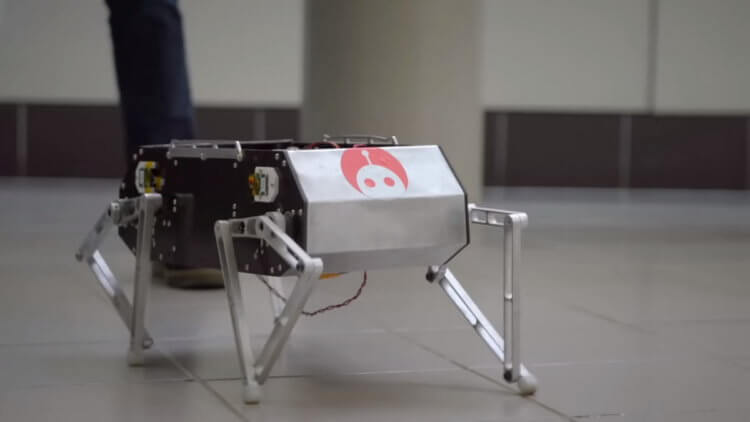

Students at Stanford University presentedfour-legged robot Doggo, designed for self-assembly. If desired, it can be assembled by anyone using commercially available components, open source software, as well as the documentation that the authors published on GitHub. In the current version of the software, the robot allows it to perform very interesting acrobatic stunts, including the reverse flip. In addition, the robot has excellent jumping ability, which allows it to bypass other robots of similar design and higher cost.

Overall, the Doggo robot copies the design of others.four-legged machines, but uniquely it makes the cost and availability for self-assembly. While comparable robots can do several tens of thousands of dollars to build, the creators of the Doggo from the Extreme Mobility Lab at Stanford University say that the cost of all Doggo components is less than $ 3000.

"We often saw four-legged robotsused for various studies, but they all looked cumbersome and expensive, not like machines that you can take with you to the lab and use in your own projects. We originally wanted to make Doggo as an open-architecture project so that you can assemble it yourself without even having a large budget, ”comments Nathan Kau, head of the Extreme Mobility Lab.

The size of a doggo is 42 centimeters long and20 centimeters in width, and weight - less than five kilograms. When developing, engineers relied on the availability of components and the relative ease of assembly of the robot.

Despite the fact that the robot is quite cheap inproduction, he is able to perform tricks not worse, and in some cases even better than his more expensive to assemble. All thanks to the improved design of its foot mechanisms and more efficient use of motors. Doggo's latest torque is higher than in the same Minitaur robot from Ghost Robotics (its cost reaches $ 11,500), in addition, he is able to jump better than the much more expensive in production robot Cheetah 3 from the Massachusetts Institute of Technology.

Each leg of the machine consists of four maininterconnected segments. There are two motors at the base of the leg, which are connected to one shaft or another at the junction of the two upper leg elements via a lower belt drive. This architecture allows you to control the movement of the legs in any direction (within one plane). In addition, the additional advantage of this design is that it allows the use of engines as load sensors. Due to this, the robot can do without shock-absorbing elements. Landing strokes are mitigated by their active engine damping.

After assembly of Doggo it is necessary to installfirmware motor controllers, as well as the central microcontroller. You can control the robot remotely, giving him commands to walk, jumps and other actions.

You can discuss the news in our Telegram-chat.